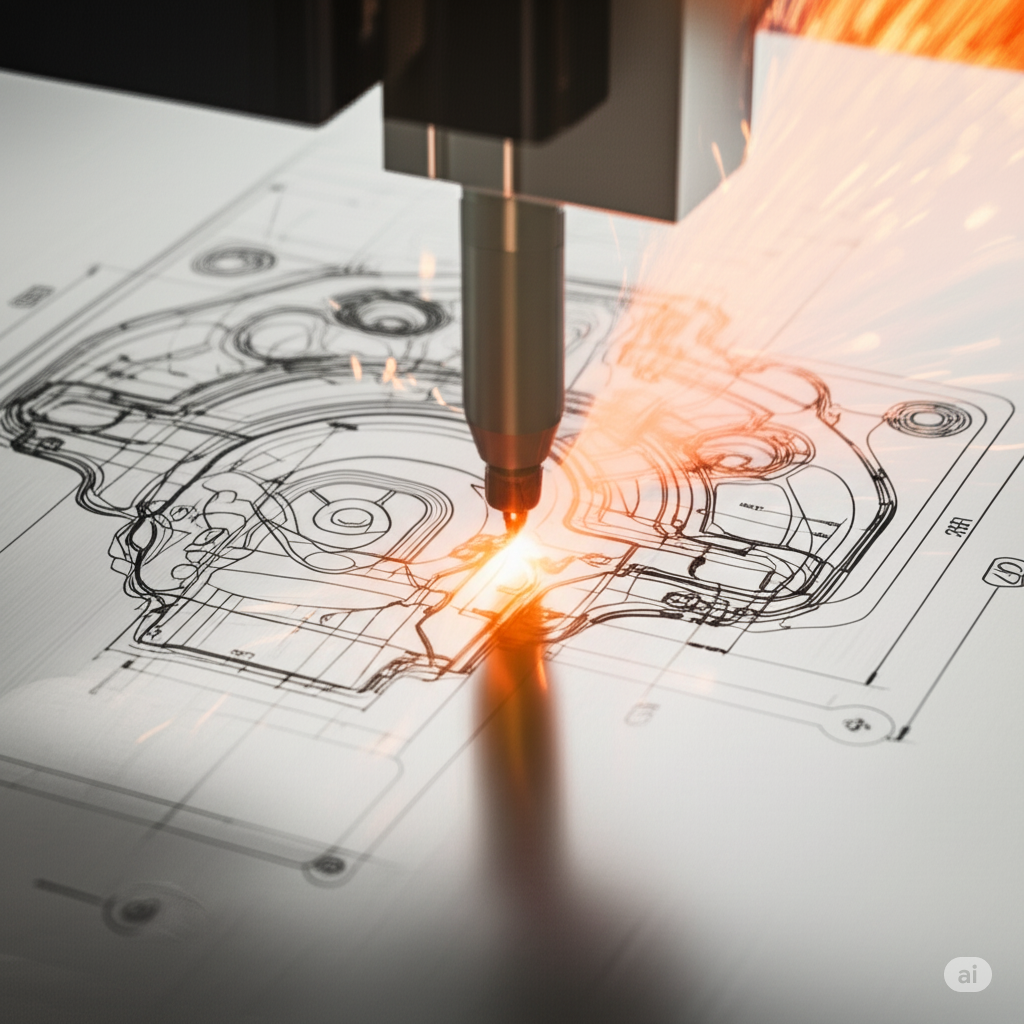

We develop print-ready 3D models with full technical accuracy—from artistic shapes to functional industrial parts—optimized for both FDM and SLA technologies.

We enhance surface quality, assign optimal thicknesses, and ensure compatibility with printer specifications—minimizing failure and maximizing output quality.

We simulate light paths, inspect vulnerable areas, and visualize the object to verify functionality and ensure flawless performance during final printing.